What is the impact of the sudden drop in temperature on the construction of plastic runways?

Release time:

2022-10-09

Recently, the whole country began to cool down significantly. Some of the plastic runway materials are liquid, such as plastic runway glue, plastic runway PU, etc.; if the temperature is too low, there is no way to construct the plastic runway.

Recently, the whole country began to cool down significantly. Some of the plastic runway materials are liquid, such as plastic runway glue, plastic runway PU, etc.; if the temperature is too low, there is no way to construct the plastic runway. In the case of too low temperature construction, the first thing that affects is the quality of plastic runway, then. Plastic runway can generally be constructed under what kind of temperature situation?

Professional plastic runway manufacturers give their opinion: generally speaking, plastic runway above 0 degrees can be constructed, but the most suitable temperature is above 10 degrees. If the construction is below 0 degrees, the construction period will be long and the quality of the plastic runway will be poor. Therefore, it is recommended that some cold winter places do not carry out plastic runway construction.

Plastic runway construction process in winter.

As we all know, many schools will use the winter vacations to build or repair the plastic runway in schools. The following is our summary of the plastic runway construction process in winter.

Preparation before construction

First of all, check whether the equipment and tools to be used are complete, whether the electrical devices are safe, the mechanical parts should be tried out, and do all the work to prevent electricity and fire. Do a good job of project allocation, engineering division of labour to implement the people, the work is divided into good, explain the importance of each project, as well as the production of matters to be noted. Once the preparations are complete the work can be started.

The objective: to ensure that the entire construction process is carried out in a safe manner, so that the quality of the work is guaranteed and the cost and duration of the work is reduced as much as possible.

Next is the technical preparation, after receiving the construction plan, we should promptly organize technical personnel to be familiar with, master the content of the drawings, construction unit personnel for drawing review, to solve the relevant matters and measures in advance. Organise construction technicians to make on-site measurements, determine the best construction plan and set out the colour effect of the surface layer after the reasonable arrangement of the process. Propose the specification, quantity and quality requirements of the main materials and the time of their arrival. Prepare the corresponding material collection plan. Reasonable deployment of construction personnel and timely entry of personnel.

Points to note

1、Check the local weather forecast before construction and prepare a suitable construction plan.

2、Do a moisture content test of the foundation, the moisture content of the foundation should be less than 5% before construction.

3, the site whether it is cement or asphalt foundation, first use PH5-6 water wet test paper test, such as PH value between 6.8-7.8 for weak alkaline foundation, with 3% dilute hydrochloric acid or oxalic acid brush site, such as PH value of 7.8-10 will use about 6% dilute hydrochloric acid or oxalic acid brush site, PH value greater than 10 for strong alkali should not be constructed, otherwise a period of time will be due to alkali migration and rubber surface delamination;.

4, the best construction conditions: temperature between 10 ℃ -30 ℃ (Note: the northern areas of the snow all year round, the temperature below 5 ℃ is no longer suitable for construction! (Southern and central regions in winter, after noon during the day, the temperature has a chance to be above 10 ℃, or can be constructed!) , humidity between 30% and 85%.

5, goods storage environment: recommended ventilation and dry indoor storage, temperature between 10-30 ℃.

Use of auxiliary materials

1, the amount of reinforcing rubber: catalyst to effectively control the main material chemical reaction speed, high temperature to adjust to the reaction speed and construction speed synchronization. For example, the mixed plastic runway middle layer, the material reaction speed is too fast to spread, the reaction speed is slow all the slurry flow down the bottom layer, wasting materials, while the bottom layer lost elasticity due to more filling materials.

2, the amount of dispersed glue: thinner effective control of the main material viscosity, according to the temperature adjustment of the amount of dispersed glue, dispersed glue evaporation speed by the temperature decision, dispersed glue evaporation speed and directly affect the effect of the surface layer. All the correlations in between must be mastered in order to make excellent plastic runway.

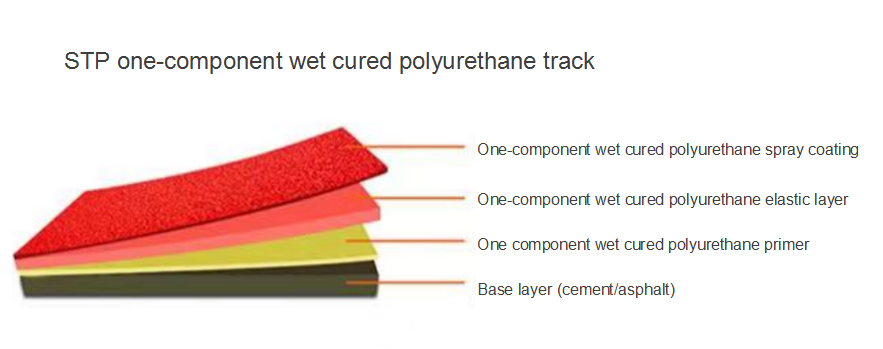

3, the amount of closed bottom glue: closed bottom glue is to cope with the use of concrete foundation, if the old concrete foundation, there are broken, long moss, prismatic marks and other phenomena application sand mill light grinding site. In the process of cleaning the site available PH test paper, (note that the temperature will affect the PH value) alkaline high recommended with about 5% of dilute hydrochloric acid splashing and washing cement base and keep dry, and then rinse clean with water (after cleaning the base surface without floating ash). After washing, dusting and drying the site (moisture content should be less than 5%), use the sealing primer to mix evenly at high speed, use a roller to carefully brush on the ground and check carefully that there is no omission of the brush, in the slightly powdered and sandy local repeatedly scraped 2-3 times to achieve the function of reinforcing the waterproof. After ensuring the dryness of the site, use the closed bottom glue to ensure the adhesion of the foundation and pu polyurethane material, playing the role of the top and bottom.

For example, mixed plastic runway base layer construction: use two-component PU polyurethane runway base rubber, the ratio of A component and B component is 1:4, the content of recycled rubber particles <25%, dispersion rubber (3%-5% of the base material, the lower the site temperature plus more), reinforcement rubber (0.5%-2% of the base material, the lower the site temperature plus more). Firstly, test paving of the site before official paving: clean and wash the delivered base, check for mechanical oil, draw a 1x1 square metre area on the site, pour in material for test paving, make records of site temperature, humidity and ground moisture content to ensure material ratios and curing times. Secondly, according to the test paving record ratios, the official blending party will pave the material.

Specific proportioning paving should also be noted when.

1. testing the thickness at any time.

2, at any time according to temperature changes to adjust the proportion of dispersion glue, to prevent the slurry is too thin, slow curing time downhill flow and cause the phenomenon of thick inside and thin outside.