STP Total One Component Moisture-curing Polyurethane Running Track

keyword;

Category:

Description

The new STP track is specially developed for the shortcomings of the current two component PU material track, which can completely solve the problems existing in the plastics industry. It realizes direct construction on cement foundation and asphalt foundation without on site weighing and stirring, have high construction efficiency and also reduced construction steps, saves labor cost, it remains excellent product performance with superior decorative effect.

The STP Total One Component Moisture-curing Polyurethane Running Track is also designed to provide excellent shock absorption, which helps to reduce the risk of injury during athletic activities. Overall, this type of track is a popular choice for high-performance athletic facilities and is known for its durability, safety, and performance.

Features

| Features of STP Total One Component Moisture-curing Polyurethane Running Track | |

| Environment friendly | Easy to operate and safe construction |

| Product performance is stable | High strength high elasticity |

| High wear resistance | Solvent resistance |

| Excellent aging resistance | Physical properties are superior |

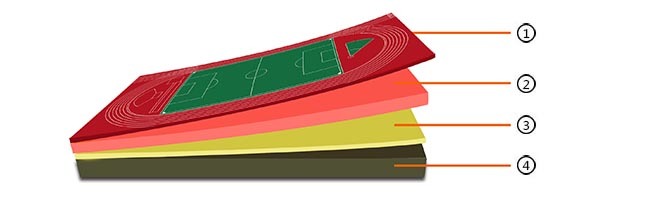

Construction Steps

1.Top Layer -A new type of rare earth modified one component moisture curable polyurethane spray coating.

2.Middle Layer -Full PU / PU sandwich, with one component solvent free polyurethane elastomer.

3.Primer Layer -Solvent free one component polyurethane primer.

4.Bottom Layer -Cement or asphalt foundation.

Construction Process

Foundation Cleaning: Washing the foundation with a high-pressure water gun to provide a dust-free surface for contact with the ground, the removal of the empty drum's base component; cutting in a V shape on the cracks. The base layer's moisture content must be less than 8% prior to the construction of the subsequent procedure, and the foundation cannot be oily.

Foundation Repair: Due to the performance of the asphalt foundation, elastic repair materials cannot be used for the depression and crack repair while using asphalt primer material. The surface material will still look fragmented as the foundation keeps cracking. The flatness must be less than or equal to 3 mm before moving to the next step.

Primer Development: (Different grassroots according to different construction requirements). According to the asphalt primer: cement: quartz sand = 1:2:4 ratio fully stirred evenly, using a 2 mm serrated scraper evenly applied to the foundation surface, to be cured after the next process.

Caulking (limited cement foundation): After the primer is dried, the 'V' groove along the expansion joint is opened, the caulk glue is scraped into the seam, and the caulk glue is flattened with a mill higher than the base surface after drying (Elastic tensile elongation is larger than 600%).

10 mm thich one-component wet curing solvent- free polyurethance elastic layer, elongation at break ≥ 600%, tensile strength ≥ 1.0 MPA.

3 mm thick one-component polyurethane self-knotting spray layer: 1-3 times, requiring no leakage bottom, provides uniform surface.

Scribing: Measure the size of the loft, use a professional scribing machine to scribble (White), and requiring uniform spraying.

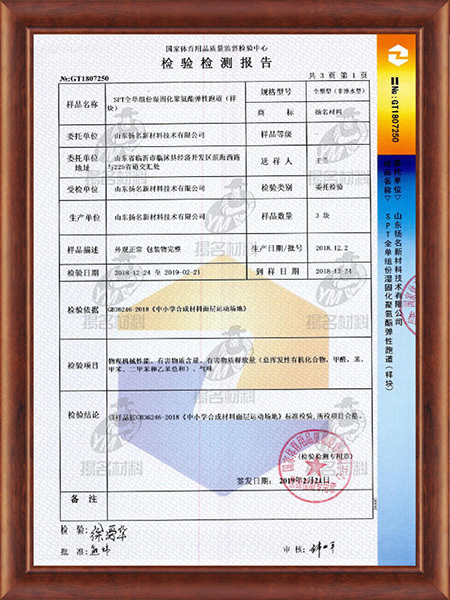

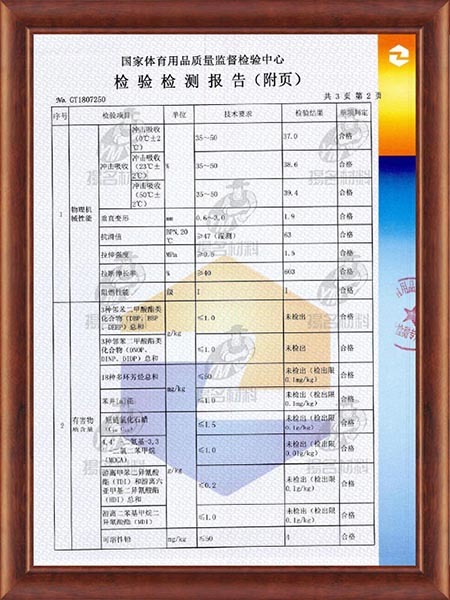

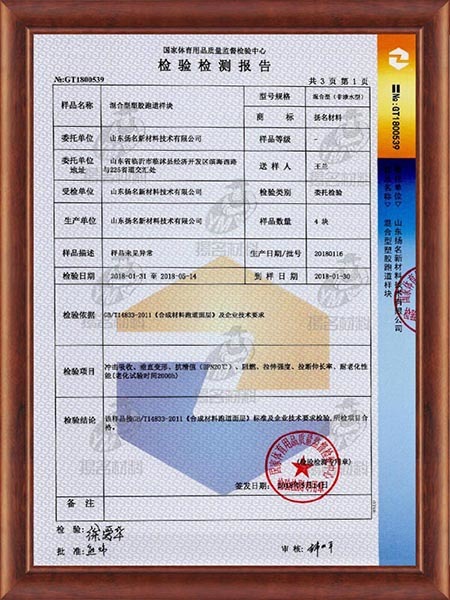

Honors

Application field

It is suitable for:

All–weather indoor and outdoor sports fitness venues;

Sports venues with high impact requirements;

High-strength plastic runways;

Fitness squares and trails, and so on.

Package and Shippment

FAQ

Q1:Are you a factory or a trade company?

A1:We are an industry and trade company.Welcome to China factory inspection.

Q2:What is thickness for the IAAF Running Track?

A2:The International Standard thickness is 13mm.Other sizes are available as your request.

Q3:Can we get installation support if we have no own constructors?

A3:We can send salesmen and technical support to your country to assist the installation.

Q4:Are your running track materials safety?

A4:Yes,our materials are safe.Environmentally friendly and recyclable.

Q5:How do you make our business long-term and good relationship?

A:1.We keep good quality and competitive price to ensure our customers benefit;

2.We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Q6:What is your terms of payment?

A:T/T 30%as deposit,and 70%before delivery.We'll show you the photos of the products and packages

before you pay the balance.

Q7:What is the Production time?

A:It is about 10-15days.

Q8:What are the options for the base construction of a running track.?

A:The ground is based on asphalt or concrete.

Q9:What is the life Span for Running track?

A:The life span is about 10-15years.

Q10:I am Interested in Synthetic track surface,what is the best choice?

A:We have 4 system:Spray coat,Sandwich,Full pour and Prefabricate system.

Message

We will contact you as soon as we receive the information